Lithium Polymer Cell Balancer

These are the plans for my Lithium Polymer Cell Balancer / Charger

Goals/Background

The goal with this simple inexpensive little device is to make it easy to check the balance of the cells in 2S and 3S packs. If it was not simple to check, chances are that I would not check then as often as I needed to. I also wanted an easy way to balance the cells once I found one that was out of balance. This little device does both in one simple and elegant design.

There seems to be no standards to how each battery manufacture handles their balancing taps. I also did not want to be tied down to one manufactures batteries. Hence I came up with my own system! Another goal was to keep connector count down as low as I could, and use inexpensive readily available connectors stocked by my LHS.

A little background on my battery set ups. I have standardized on 2 connectors for all my batteries. I use Deans Ultra on all packs that I will be using at 10 or more Amps, and Deans Micro Polarized on all smaller packs. I only have and only plan to have 2s or 3s packs. If I need something more, I will simply add packs in parallel or in series to get to the larger amps or volts as needed. This makes my charging and cell maintenance very simple. If a plane is big enough to need a larger cell count, the additional weight of the connectors should not make a difference.

This also makes ordering packs simple, as I can order them with the Deans Ultra's and only have to add the JST connectors. I used the male JST connector for the taps as they work better under the heat shrink.

All my chargers also have Deans Ultras male connectors on them. I use adapters that I make to go from the Deans Male to anything else. This simplifies charger cord management, and also makes bringing cords into fire proof containers to charge all my LiPo's much simpler.You are free to substitute what ever connectors you like, or you can adapt my personal preferences if you like!Building

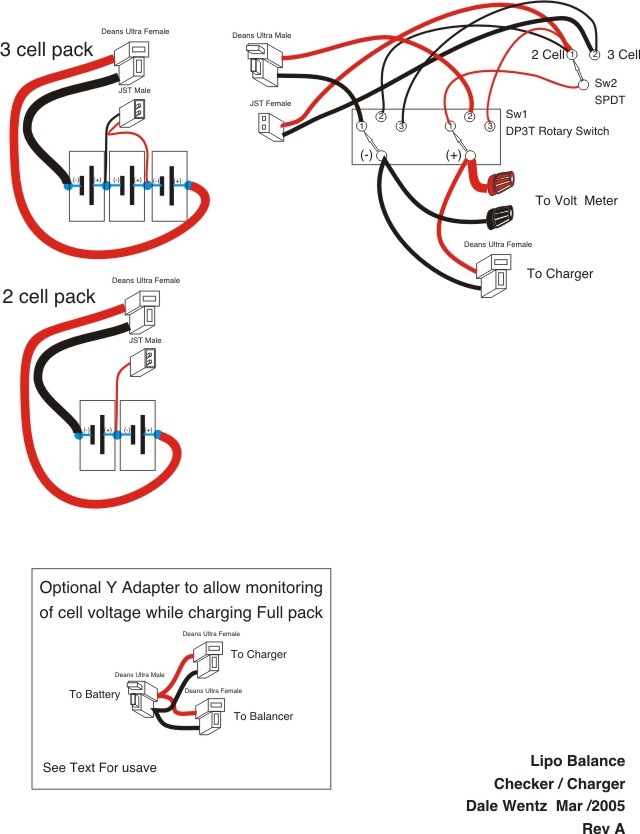

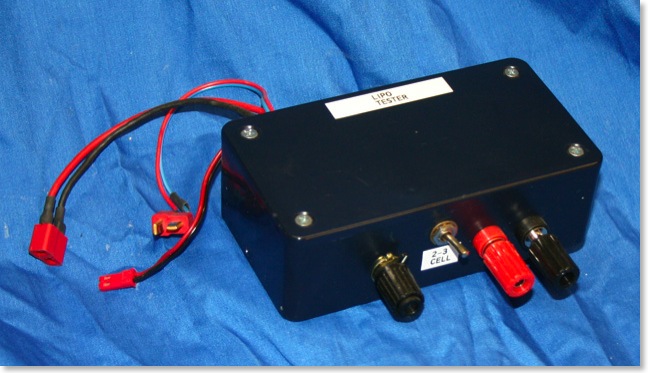

My Balancer / Charger is a simple device. The only components that you need to construct it is a Double Pole Triple Throw (2P3T) roatary switch (SW1), SPDT Switch SW2, knob, case, banana jacks, and connectors of you choice. Depending on the switch you use you might need a small circuit board from Radio Shack like that one in the photos. I used a switch I had on hand, Some other possible substitutes are listed at the end. One thing you want to make sure is that you get a "Break before Make" type switch. This simply means that if the switch is in position 1, Position 1 will be disengaged from the common connector before position 2 is engaged. Most Rotary switches work this way.

Unfortunately manufactures don't always list this with their switches. I used a 4P3T (4 pole 3 throw) switch I had on hand. allelectronics.com has a switch listed that should work well for this project, and does not need a circuit board. Link to the switch (You will only use 2 of the 4 poles on the switch) Don't forget to order a knob and a small project box.

Radio shack also sells a 6 position switch that would work. You would only use the first 3 positions. It is part number 275-1386 and is listed as a 2-pole, 6 positions. Non- shorting. Rated 0.3A at 125VAC. This is $3.29 and stocked by most Radio Shack stores

SW2 Selects between 2 and 3 cell operation. Be sure to set the switch for the proper set of cells before connecting. If you have it in the wrong position you will get wrong meter readings. Nothing bad will happen.

Using

Testing:

Set the 2 or 3 cell switch to the correct position

Put the tester in position 1

Hook up your volt meter to the banana jacks.

Hook up the battery to be tested

Read the voltage on meter for each switch position.

(NOTE: On a 2s cell you only use the first 2 positions)

Please note that the size and length of the wire on the balancer/charger could give you slightly different voltage reading due to the resistance causing a small voltage drop in the length of wire. When I built mine I tried to use approximately the same size and length of wire for the leads going to the packs under test.

Out Of Balance:

Normally you will find that 1 cell reads a little low, and 1 cell reads a little high. In most cases the high cell will be more than the 4.2 volts if you charged the pack to its full capacity and have a pack that is out of balance. This is one of the reasons that packs fail, by ballooning or bursting into flames. This is one of the reasons that it is important to check and fix the problem on a regular basis. A typical charger only looks only at the voltage of all the cells in series! If one cell is exceptionally low, it will allow one of the other cells to be charged to a higher than recommended voltage to make up for the voltage in the lower cell.

Balancing:

Packs should be balanced when they are fully charged or close to being fully charged! I charge my cells to 4.1 volts per cell, by setting my Triton charger to Lithium ION. This should charge the packs to 4.1 volt per cell (.1 volt under the max) This will undercharge a 3S pack by .3 volts . I then check my pack with the checker. If I see an imbalance I then charge each cell up the the 4.2 volts individually. If I find a cell that is higher than 4.2 volts by a bit, I slowly discharge the pack until that cell is under the 4.2 volts max. Then I charge each cell up to the 4.2 volts.

Hint:

If you do not have the option of charging to a lower voltage per cell, you can simply stop the charge early. You want to stop the charge at about 4.0 to 4.1 volts. Then check the pack, and charge each cell up individually to the 4.2 volts per cell.

Charging:

I use my Triton charger to charge each individual cell in the pack as needed to bring them in balance. Select the cell you want to Charge with SW1. Then simply set the charger for 1s (4.2 Volts) and charge as needed. Keep in mind that the taps are light wire, and you need to charge and discharge at very low amperage. I never exceed .25 amps! The other nice thing here is that you do not have to plug and unplug you pack while testing each cell, all you have to do is move the switch!

Triton Note:

You can use the volt meter in the Triton to check the balance of each cell. No external volt meter is needed. The internal volt meter is enable by pushing both the buttons down at the same time on the charger. The Triton also will have its volt meter displayed when you are done charging a cell. Simple use SW1 to select the cell you would like to read.

Optional Y Adapter to Monitor Cell Voltage While Charging the Pack in Series:

After building and using the adapter I wanted the ability to monitor the voltage of each cell while charging the batteries normally in series. This way I could stop the charge when 1 cell reached 4.2 volts, as well as check for gross imbalances in the cells during charge. I thought about adding another switch to the Checker/Charger, but after working the schematic out I decided it would be safer to build a simple T adapter. This would eliminate the error of having the switch in the incorrect position and charging one cell at the 2S or 3S rate. Even if your charger auto-detected the mismatch the possibility of the switch being moved after the charge started would pose too much of a danger.

To use the Y adapter Hook up your volt meter to the Checker/Charger. Plug your charger into one of the female connectors on the Y adapter. Plug the Deans Male from the Checker/Charger into the other female plug. Connect the battery to the Male connecter on the Y adapter and the JST connector from the Checker/Charger to the battery. Note: that the Deans female connector on the Checker/Charger is not connected to anything when using the Checker/Charger in this mode!. Set your charger up to charge the battery in its normal mode. You may now use the switch on the Checker/Charger to monitor the voltage of each cell during the charge. If you notice an imbalance monitor the highest cell untill it reaches 4.2 volts. Then terminate the charge. Remove the Y adapter, reconfigure the charger for a single cell charge. Connect the Battery to the Checker/Charger. Connect the charger to the female Deans connector on the Checker/Charger, and top off each cell. When you are completed you should have a balanced pack.

Disclaimer:

If you are not familiar with the use and abuse of Lithium Polymer cells, and the in and outs to building and balancing packs, you should not attempt to build this! You should know what you are doing before playing around with electronics and Lithium Polymer batteries. This is a design, that I came up with that works good for me. I am not an electrical engineer, just a simple hobbyist. Use at your own risk, as I said I am not an expert This is simply documentation of the system that I use. Please take all charging and handling precautions when working with Lithium Polymer Batteries!

More Information:

Lipo Cells Charge to 4.2 volts per cell!

Never discharge to below 3 volts!

The resting voltage of the cells should match!

You should check your packs after they have charged, and set for a bit.

If you discharge and charge one cell you will have to wait for the cell to settle before taking a voltage reading again.

This is one reason that charging each individual cell up from a not fully charged pack is a good idea!

Internet Links:

There is lots of good info at the rcgroups.com site.

Check out the battery forums and be sure to check out the Ultimate Guide while there!

Ultimate Guide to Lithium Polymer Batteries at RCGroups.com

A Review of Cell Equalization Methods for Lithium Ion and Lithium Polimer Batteries

Schematic