Technical Reference on the Clausing 8520 / 8530 Mill

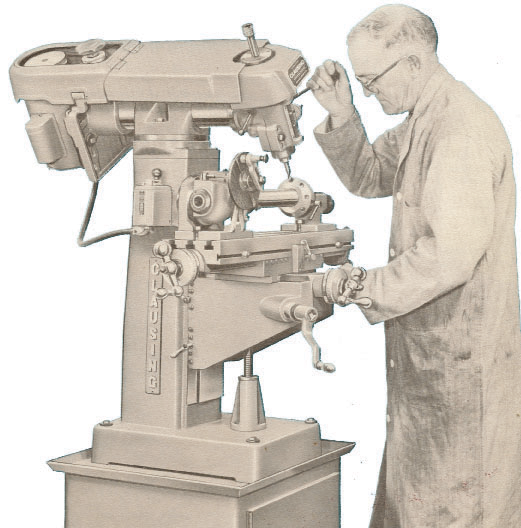

The Clausing 8520 is a highly sought-after small knee mill due to its versatility and light weight. I can be broken down into lighter pieces and easily moved, even up or down stairs. This makes it ideal for the home shop.

History:

The 8520 was main mass-produced model of this mill.

The 8520 and the later 8530 both came with a Morse Taper 2 nose spindle. There were also models 8525 and 8535 that contained a Brown and Sharp #7 taper spindle.

The Morse Taper 2 spindle is much more desirable due to the lack of availability of the B&S #7 tooling.

The mill was offered in many other variants during its life:

- Model 8512 that was sold without a head, or custom configured to other applications

- A model was offered fitted with a Bridgeport M head

- Some early models left the factory with only hand wheels on the right side of the table.

- Some early models have been reported painted in tan instead of the customary gray.

If you are interested in more history on these machines head on over to Tony Griffiths wonderful site. There you will find a treasure trove of historical information on many machines besides the Clausing mill. The 8520 page is available here.

There are some other pages on the net with information on this milling machine.

Parts and Tooling:

Some parts and manuals for this mill are still available from Clausing.

Clausing contract information:

811 Eisenhower Drive South Goshen, IN 46526

Phone: 800-535-6553

My archive of documentation

- Owners Manual and Parts Diagram

- Sales Brochure

- Color Catalog showing available options

- Blank Test Report

- 8635 Power Feed Manual

- 8630 Measuring Attachment Manual

Tooling:

New Morse Taper 2 tooling is readily available, due to some of the newer import milling machines also taking MT2 tooling. Depending on your draw bar configuration (See Below) all the tooling should be 3/8-16 threaded.

Besides eBay I have purchased tooling from the following.

- LittleMachineShop.com has lots of MT2 tooling and arbors available.

- CDCO Machinery also has some MT2 tooling.

One of the questions that come up from time to time is what size vice and what size rotary table works best on the mill. I have a Enco Model #425-7240 vise without the swivel base that I purchased which is a good fit for the mill.

I have a small 4 inch rotary table, but a 6 inch fits nicly also. A 8 inch is really too big for the table.

I have a small 4 inch rotary table, but a 6 inch fits nicly also. A 8 inch is really too big for the table.

DRO

I have installed a DRO on my mill.

Replacement Belts

The Mill uses standard automotive type 4L belts.

Part Numbers are 4L-220 and 4L-480

T-Nuts

The mill table uses 9/16 T nuts.

I find that the 1/2 inch T Nuts work fine also.

Drawbar

Over the life of the 8520, there have apparently been several variations on the drawbar design. The earliest ones had a ring brazed onto the 3/8-16 drawbar, which fit under a large knurled nut on the top of the spindle. The end of the drawbar was ground 1/4 inch square. A supplied small right-angle wrench to loosen or tighten the drawbar was provided. The ring would either push or pull, so you could eject the collet by simply loosening the turning the drawbar. This is a nice set up and saves the need to use a hammer to eject the tooling. My mill has this set up, but was missing the wrench. It’s an easy project to make one. I built mine from a 1/4 inch socket and a 1/4 inch hex wrench, works great! (See my projects page)

Later drawbars used two nuts on the top of the drawbar, still leaving the big knurled nut on top of the spindle. This required the use of a brass hammer to dislodge collets.

The last batch of machines they made didn’t have threads on the top of the quill for the knurled nut, the bottom nut on the drawbar rode directly on the top of the spindle. You still have to use a brass hammer on these.

Restoration Information

Much of the following information I have collected from other sites, forum postings or e-mails with fellow 8520 owners.

Reported Paint Color Matches

One user found this was a match on his mid-60’s 8520.

The paint was color matched by a local paint dealer to a small part that I brought in to the store.

Benjamin Moore paint, labeled “Urethane Alkyd Gloss Enamel Base 4 M22 4A”

The color code is:

RO-1

TG-20

BK-6×2

OY-3×27

Another user color matched the paint on his mill and found Benjamin Moore & Co., Urethane Alkyd Gloss Enamel “1567 Night Train”

They use a Deep Base M22 3B to start with, and then add the following tints.

UTC Gallon Formula:

OY 0x21.00

BK 1×28.00

TG 0x10.00

WH 1×4.00

Quill

Quill Drive Plate Spring Plungers:

Apparently not all mills came from the factory with these installed. Some mills have been reported to have nylon plungers installed instead of the brass. The plungers are adjusted for quiet running and for added drag to hold the quill from dropping easily.

These are 1/4-20 screws 180 deg apart drilled/tapped into the plate edge.

The brass/nylon plungers bear on the high parts of two splines.

If you mill does not have them its an easy job to add them.

Each hole is directly opposite from the other (on diameter).

Drill thru 13/64 dia (oversize) to the center, centered on the edge of the drive plate disc. The holes are also centered on a gullet of the drive plate spline.

Tap the hole 1/4-20 about 1″ deep. Make a brass plug to be a slip fit in the hole 3/8″ length. Fit a coil compression spring (.028 dia wire x .26 long x 3/16 dia) to sit on the plug. Adjust the set screws to compress the spring and push the plug onto the spline.

Lead Screws

David Shaw’s Site (No longer available), Had an article on replacing the leadscrew with standard 3/4 inch acme rod.

(PDF copy of David Shaw’s article.)

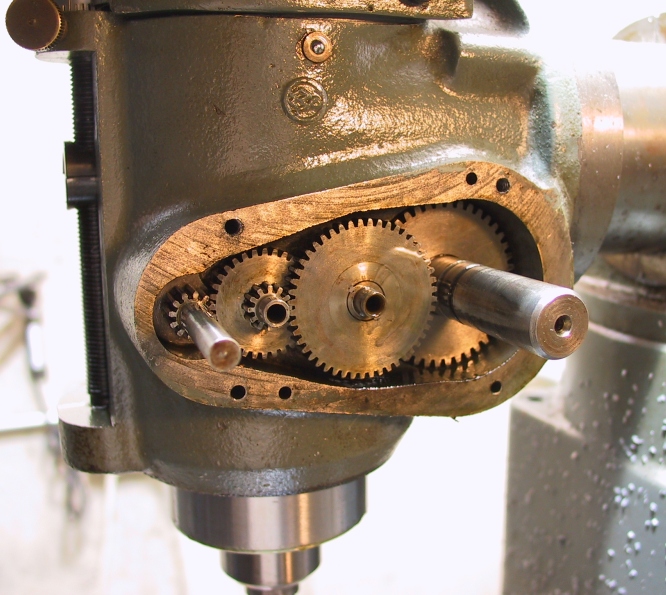

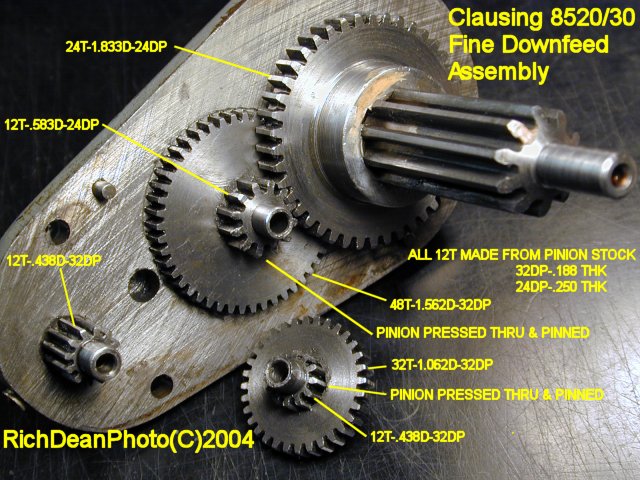

Gears

The gears in the quill can easily be broken. Here are some notes I collected on replacement gears:

One owner found one of the gears in his mill was marked Boston Gear S-3232.

Their online catalog shows this to be a 32 DP 14.5 degree PA 32 tooth

The last pinion that drives the last gear that slides on the spline is 24 DP instead of 32 DP.

It turns out that the small spur gear portion of the 8520 compound gear (Clausing part 990-065 – cost $66) is a close match to McMaster-Carr part no. 6325 K31. Cost $7.79. A bit of cutting to get the hub thickness down to 1/4 inch, some finish sanding and reassembly using 1/4″ dia. cold rolled stock as a shaft and a broken length of 1/16″ drill bit as a pin to lock the two gears – and everything works. Whole job took about an hour and a half.

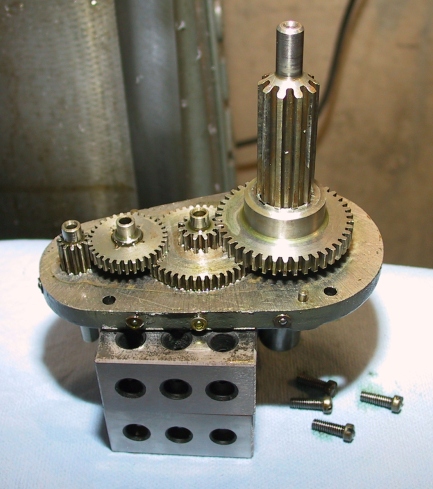

When I purchased my mill the gears seemed a little crunchy. It turned out that they were just dirty with dried grease. Here are some photos I found on the net that show the gear placements.

Rebuilding the Mill Head

There are two nice articles on rebuilding the head on this mill.

Dennis Pantazi on changing the bearings – Link – Local PDF

Fred did a wonderful job of documenting his rebuild – Local PDF

Bearings

All the bearings with the exception of the lower spindle bearings are commonly available. The Lower head/spindle bearings are a Class 3 which is specified as having a total runout of 0.0003 or less. They are sold as a ground matched set . Unfortunately they are no longer available from Clausing.

Lower head / Spindle bearings

Qty 2

Clausing number 044-005

Size (25x52x15)

Use Fafnir 7205WNSU

These are 39 degree angular contact bearings.

They are flush ground for minimum preload when duplexed (2 bearings together)

Upper Head bearing

Qty 1

Clausing Part Number

Use Fafnir 304KDD or, sub 6304ZZ/ND 3304/KBC 6304

Size 20x52x15mm

Upper spindle bearing

Qty 1

Clausing PN 044-016

Size 20x47x14mm

Use MRC 204SFF, FAG equiv to

Use Fafnir 204KDD, 6204ZZ,304KDD

Spindle driven step pulley bearings

Qty 2

Clausing PN 044-007

Size 25x47x12mm

Use Fafnir 9105KDD, Fafnir 9105KDD, 6005ZZ

Tables and upper idler pulley

Qty 6

Clausing PN 044-004

Size (12x32x10mm)

Use Fafnir 201KDD, Fafnir 201KDD, 6201ZZ

Lower Idler pulley

Qty 1

Clausing PN 044-003

Size 15x35x11mm

Use Fafnir 202KDD, Fafnir 202KDD, 6202ZZ

Knee screw upper thrust bearing

Qty 1

Clausing PN 044-011

Use Andrews D-3, standard D-3 thrust bearing for replacement

Size A .625 – B 1.244 – C .563

Knee shaft bearings

Qty 2

Clausing PN 044-008

Use NICE 1607DS, 1607ZZ, 1607

NICE 160105 (Part Number of bearings in my mill)

Size A 7/16 – B 29/32 – C 5/16